Infill Panels For Windows for Beginners

Table of ContentsFascination About Railing Infill PanelsEverything about Infill Panels For WindowsPerforated Metal Infill Panels Fundamentals ExplainedThe Facts About Lightweight In Fill Panels UncoveredSome Known Details About Infill Panel How Pvc Infill Panel can Save You Time, Stress, and Money.

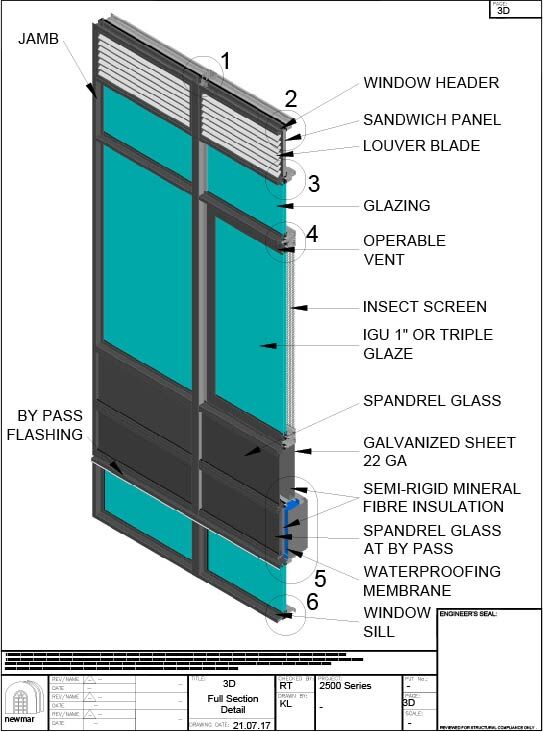

A service to these concerns for a conventional curtain wall system was found as part of ASHRAE Research Project 1365 "Thermal Performance of Building Envelope Particulars for Mid- and Skyscraper". A standard drape wall system at a floor piece crossway with an uninsulated stud cavity was compared to the exact same system with 50 mm (2 inches) of closed cell spray foam in the stud cavity.Including insulation into the back-pan has a similar decreasing rate of return for both systems since the aluminum structural members bypass the backpan for both situations. Adding spray foam inboard of the back-pan outcomes in an 80% to 115% improvement in general thermal transmittance (U-value) but still falls brief of the performance usually gotten out of opaque aspects for mild and cold environments.

5 (2 inches of foam) of insulation to the system just resulted in a boost in overall (effective) thermal resistance of about R-4 (mapes metal panels). This is frustrating however not surprising offered the substantial amount of heat circulation that can stream through components bypassing the thermal insulation; piece, anchors, and perimeter stud framing.

The Greatest Guide To Perforated Metal Infill Panels

43. This is a 1 to 3C distinction in surface temperature or a 2 to 4% RH difference in optimum indoor RH without the risk of condensation for moderate and cold environments. These outcomes indicate that the distinction in condensation resistance is acceptable for when indoor wetness levels are managed however needs better evaluation for areas with unrestrained indoor humidity (most property structures).

Strategies making use of element modeling of 2D sections is well developed in our industry; treatments established over many years to examine the thermal efficiency of glazing systems provide adequate precision for constructing design. This MH solution highlighted an exception where more complex treatments are necessary. This example offered insight into the relative efficiency in between a conventional drape wall spandrel panel with insulation only in the metal back-pan and a composite system with insulation likewise provided inboard of the back-pan.

What Does Pvc Infill Panel Mean?

First off, spandrel panels need to supply insulation value in addition to moderate impact resistance. Our spandrel panels make use of aluminum skins, with MDF core for effect resistance and tightness. The 1 panels make use of an XPS foam core to enable maximum R worth. Panels can be used in both outside and interior applications, and can be found in a range of colors.

H&H can make a range of various sizes and colors, even custom painted spandrel panels if required with moderate preparations. A specific adhesive is utilized and, panels are produced to stringent flatness tolerances. This guarantees the greatest quality appearance, and efficiency versus panel delamination.

The Single Strategy To Use For Mapes Metal Panels

Spandrels are horizontal precast pieces that may be structural with pockets, corbels or ledges to support double tees and hollowcore plank, or non-structural components in total precast buildings and parking garages. Spandrel panels been available in different sizes and shapes depending upon the job. Normal spandrel lengths are 30-0, 36-0 and 40-0.

Metalline's ongoing dedication to R&D has actually seen them time and again attains firsts. Metalline was the first UK fabricator to be able to offer 6000mm x 2000mm spandrel panels. Now after additional investment Metalline is among the very first UK producers to be able to provide a A1 (non-combustible) spandrel panel checked to EN13501: 2018.

Structure policies set the standards and standards for the thermal insulation, which is required within wall building. This applies to both brand-new construct and repair jobs, where the thermal insulation efficiency is expressed as a U worth. For recommendations on how to fulfill specific U worths to comply with thermal efficiency requirements, contact our technical team.

The Single Strategy To Use For Steel Infill Panels

Using insulation cores checked by The Noise Research study have a peek here lab, Metalline can produce insulated spandrel panels for almost every environment. They have actually been successfully defined on structures in high sound locations such as airports, city centres and commercial environments. At Metalline, non-combustible cladding and fire resistance are of the utmost value.

Making the variety best for new build or the replacement of non-compliant spandrel panels. Our aluminium spandrel panels are readily available in a variety of finishes. Our anodised surfaces, a few of which are noted below: Bronzes (light to dark) Natural SilverBlackRegency Gold I & IIA more natural result can be accomplished with II Blue-Grey and Stone-Grey colours from expert Anolok anodising.

We likewise have a full variety from this source of Pay Per Click finishes readily available which A2 fire rating can be achieved with. Please download our pamphlet for comprehensive info on the Spandrel Panels and Systems we provide in addition to quality drawings of all the systems. Please note that our spandrel panels do not connect to timber celebration wall panels and gable panels.

The Mesh Infill Panels Ideas

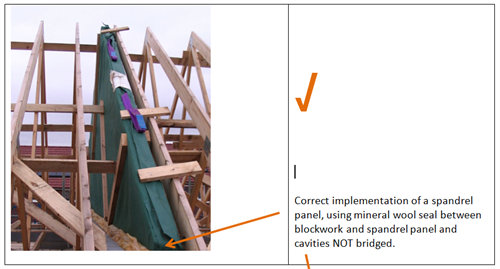

As an option to traditional masonry gable ends and separating walls within the roofing system area, TRA members progressively use a roof structure style that includes prefabricated spandrel panels. Delivered as part of the trussed rafter package, spandrel panels are pre-assembled structural panels used as a separating wall or as an external gable roofing panel.

Offsite manufacture saves valuable on-site time Single see this trade option removes the requirement to co-ordinate different trades Efficient and flexible Lowered extra scaffolding expenses No cure time needed prior to roofing setup Click on this link to get a no obligation quote or to discuss your next task.